So we end this week with the project not looking that much different to before however this week has really been all about the suspension.

Having fed penetrating oil into the seized swinging arm bolt for the past week the bike was put upright and I hoped for some movement. Nothing. So the challenge was to get the bolt out but without damaging the threads on its end. Time to reflect is always useful and I wondered if the bolt thread was the same as on the front wheel spindle of a Jota/RGS (remember you use this to pop the alternator off its taper)? I was in luck so it was out with the trusty Honda VT500 wheel spindle and I threaded this so half the nut was on the frame bolt and half on the spindle thus ensuring no thread damage. You can see it needed a little persuasion but soon it tapped out 🙂

After and before (should’ve put them the other way round)

I cleaned up the bolt, working hard to get a good surface for the bearing in the swinging arm to seat on. However it began to dawn on me that the swinging arm worked in the same way as the suspension wishbone i.e. there is a bush that works on a plain metal bearing.

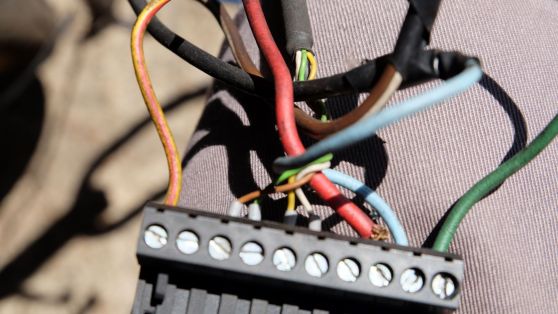

Rusted inner bush which in turn is rusted to the plain bearing

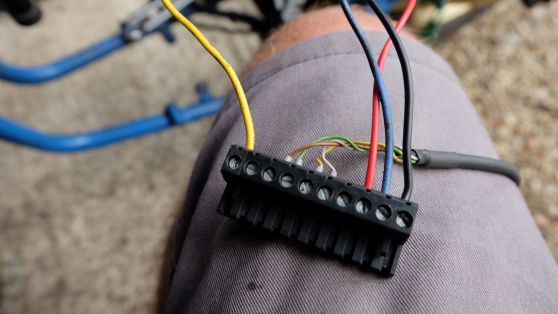

Sure enough in all the mess there is indeed a bush and bearing. What happens is that the bush seizes on the bearing which then means the bolt becomes the pivot point. If I was to buy another Atlas one thing to check is as you bounce up and down on it do the swinging arm end bolts move? If they do then the swinging arm is seized! Lucky I had spares on the shelf so next stop was to press out the old bearings.

I spent a few hours with the vice, Radio 4extra, old imperial sockets as spacers and a big hammer. I then repeated this exercise on the suspension knuckle. The tough part of this is getting the seized bush out of the plain metal bearing. Once this is done the plain bush pressed out (and in) with relative ease.

Complete suspension knuckle just needs the o ring seals

The final job was to paint the rusty swinging arm. I’m not trying to make the bikes look concours (surely not) so some Hammerite Gold was pushed in to action just to stop further deterioration.

Note chain adjustment sticker – another reason not to go for full paint job

So the suspension on the Atlas is something that requires regular maintenance – it needs to be stripped twice a year to ensure things don’t start seizing! The plain bearings are things you can buy from a bearing factor but the ‘spacer’ bushes don’t seem so easy to locate (especially the long bush in the centre hole). The other thing not to forget is the o rings as these are all that stand in the way of muck getting to the bearings. On this subject it’s worth noting that the o rings get messed up by oil (despite probably being viton) as on both bikes the swinging arm bearing on the chain side was the really seized item and in both cases the o ring between the frame and swinging arm had rotted.

Finally a a nice surprise came through the post in the form of two repaired centre stands for the RGA/S. Clem had welded in sections on all the legs where they’d whittled holes in themselves through rubbing the underside of the exhausts (funny you’d think the exhausts would come of worse hey). Clem had then moved on to the locating holes which were oval. He’d welded these up and re-drilled them and chucked in some new stainless bearings. It’s a top class bit of work and easy to underestimate how much work went in to restoring parts that are becoming expensive and difficult to find. A big thanks 🙂

Nick 🙂