Success!

After a week of fiddling with the details of the Atlas it runs. Having got the engine in I had to hook up all the bits and pieces. Luckily I had a week off work so rather lazily set about the tasks. The main challenge was to install new exhaust manifold studs into the head as these had been removed.

I got new studs from Slater Laverda and first ran an M6 then the correct size M7 tap in to clean up the threads. Pleased I did this because the fresh studs went home a lot cleaner and I wasn’t on the edge of a busted thread or stud which would’ve required the removal of the cylinder head.

Initially the bike was reluctant to start and I thought it was going to involve resetting the ignition timing or back to the carb…but a little bit of cranking and it fired up – on two! After warming through it has a solid tickover – from cold I find it needs choke (I installed the coat hanger bodge as I prefer it over a cable) initially but it fires easily. All this two cylinder fun was briefly halted when once again it went onto one – investigation showed however that I hadn’t screwed the pilot jet screw home properly and there it was sitting on top of the crankcases! Everything restored and back on two.

What a difference on the road – the engine is so quiet mechanically. It’s never going to be a powerful bike but it makes decent enough progress.

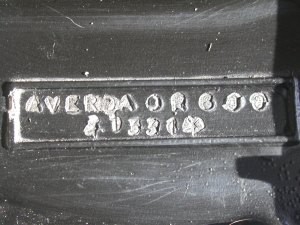

So that’s taken some of the pressure off – one decent sized Laverda for the 2014 season. To push the advantage home I also got my registration papers off to the VMCC. This starts the process of registering my second (and complete) Atlas for the UK. It’s looking like 2014 is most likely going to be a 100% twin year though maybe not as now I can focus on getting at least one of the triples ready for the road.

Nick 🙂