Bugger!

Riding to get the Atlas checked over for its roadworthiness (MOT) certificate I was struck by two things – first off how sweet the engine seemed after the horror of Atlas #2 and secondly how useless the rear brake was! I knew it was bound to fail but better to set a benchmark and know what work was officially required – time is running out for the Welsh Rally next weekend!

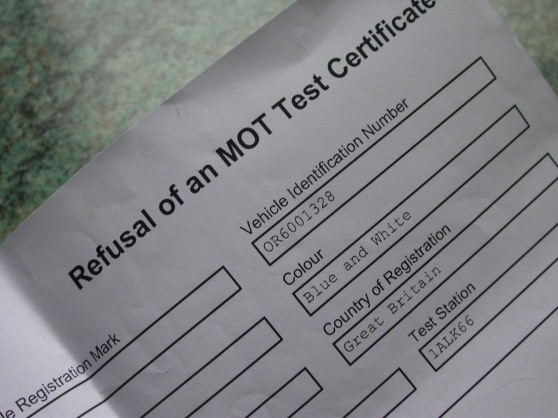

Sure enough the brake was less than 25% effective but the good news was that everything else was okay 🙂 So back to the garage.

Taking the pads out revealed that one of the little buttons that needed pressing into the pads had come out. I’d wondered which way they should be put in last weekend when the new pads went in and with a bit of thinking realised that they were in the wrong way round – the ‘head’ should face outwards which means that the pads are held in place before the centre pin is pushed how and should the button come adrift it doesn’t fall in to the brake disc. Lucky for me I didn’t lose the button and second time round the button was held with Loctite.

This wasn’t the reason the brake wasn’t working however – this turned out to be the master cylinder so I ‘borrowed’ one off Atlas #1.

You can use tyre irons for more than tyres…

With the calipher off and lower than the master cylinder it soon pumped up and the Atlas is ready for Tuesday’s re-test 🙂 Work didn’t stop here though as I had planned to sort out the slipping clutch and broken gearbox return spring so it was off with the primary case.

Homemade tool to hold the clutch in place

I’ve had a bit of experience of this recently so pulling the clutch apart was straightforward (once I used my new long allen keys and impact driver to remove some stubborn bolts – y’know this set of long 3/8th drive allen keys is fast becoming my favourite tool) and it turned out that the slipping is most probably baggy springs as all the plates look to have life left in them. Trouble is I have two sets of springs – one super strength items designed for Zane twins and the other stronger than standard jobbies. I didn’t label the sets (no surprise there) so just shoved a set in – the clutch now doesn’t feel so light but we’re not talking SF weight here!

A new gearbox return spring and a bit of high temp’ paint on the exhausts completed the days work which I will test out tomorrow (what could possibly go wrong). If I have time during the week I will put a new set of tyres on and chain and front sprocket but I can still do the Welsh without this – so let’s be honest it won’t happen.

So fingers crossed for Tuesday and time get planning the Welsh rally route.

Nick 🙂