So first proper frost of the winter on Saturday. I did have to run an errand on Thursday however and found winter problems had already arrived when I found the gear change bush seized in its housing. Gearchanging was like getting your wellies stuck in clay but loosening off the footpeg meant I could ride home.

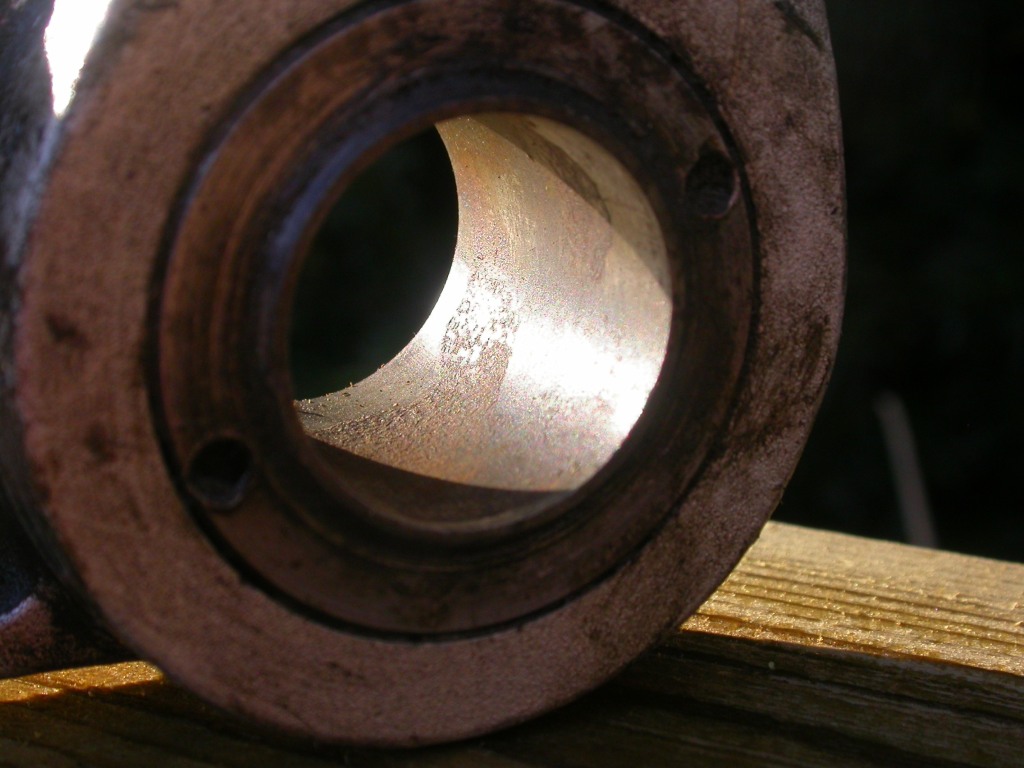

This situation was a consequence of the weekend camp in Wales. I’d noticed road salt on the exhaust clamps the day after and had washed the bike down with car shampoo and oddles of cold water. Thought all was good but a week later there we are with a seized brass bush. A simple fix – tap the bush out and clean both the bush and steel housing, liberal coating of grease and good to go.

I had sprayed water under the tank when cleaning the Jota but as a precaution it was tank off time as I didn’t want the flatslide linkages going rusty. The good news was that there wasn’t any significant corrosion so I went through it firstly putting light oil on the linkages followed by a coating of ACF50. After many years winter riding I won’t be ruining a Jota to make some kind of ‘well hard’ point but hopefully it’ll get the occasional run out. Even with the seized gearchange lever I still found myself smiling at my good fortune to be riding a Jota and revelling not only in the engine but also the surprisingly taut handling.

Talking of fixing things Andy Bartlett fixed a seized bolt in my RGS footrest hanger. The allen bolt head was mangled (not by me surprisingly) and I thought the steel head had welded itself to the alloy hanger. Turned out it was the thread that had seized although Andy only found this out once he’d welded a bolt to the mangled head to break the corrosion. Once again I congratulated myself on realising my limitations and handing things over to an expert before the ‘big hammers’ came out and something bad happened.

Finally Saturday saw the British Historic Racing awards evening at Daventry. Tony Jiminez was there to collect his trophy for winning his ‘BEARS’ class on his YB6 Bimota. The Laverda F1 team turned out to celebrate with him. It was a double celebration for Tony has Andy handed over his EEC Winners medal too

– a good night was had by all!

Nick 🙂